Capabilities

Custom CNC Machining Services from China

We offer over 40 certified materials, including a range of metals and plastics, to meet diverse customer needs.

We provide highly customizable finishing options to ensure each product meets your specific aesthetic and functional requirements.

With no minimum order requirement, we offer high-quality custom services regardless of project size.

Our short production cycles and fast delivery ensure your project stays ahead in the competitive market.

Precision CNC Machining Services Supplier in China

Are you looking for a reliable partner to provide CNC machining services?

AT CNC Machining is a leading CNC machining services supplier in China.

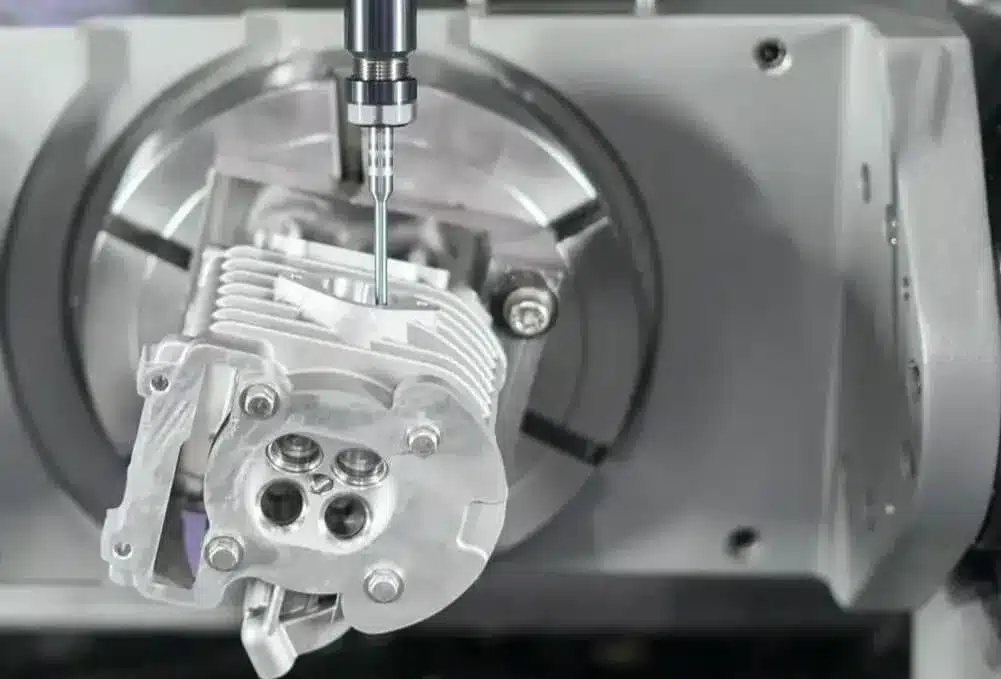

Our 3-axis, 4-axis, and 5-axis CNC milling, turning centers and CNC Lathe machine enable to make precise, high-quality CNC parts that fulfill your custom specifications.

With over 50 sets of CNC machines in China, AT Machining can be your ideal choice for outsourcing custom and precision CNC machining services. no matter your industry. Get your quote today.

3 Axis, 4 Axis and 5 Axis CNC Machining Service for simple and complex geometries parts.

CNC turning with live tools combines lathe and milling capabilities to machine parts with cylindrical features.

Add multiple finishes to your parts, such as Anodizing, Sand Blast, Powder Coat, Plating, etc.

Surface Finishes for CNC Machined Parts

Apart from custom CNC machining services, we also provide complete surface finishing options for precision machined parts. If you require custom finish not on this list, please do get in touch as it is likely we can source it for you.

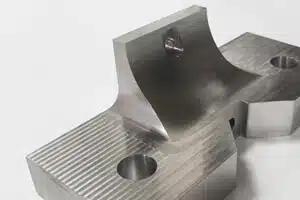

As machined (Ra 3.2μm / Ra 126μin)

This finishing option with the shortest turnaround time. Parts have visible tool marks and potentially sharp edges and burrs, which can be removed upon request.

Smooth machining (Ra 1.6μm / Ra 63μin)

Smooth machining is similar to a ‘As machined’ finish, but with less visible machine marks. Parts are machined at a lower feed rate, with no hand polishing.

Polishing (Ra 0.8μm / Ra 32μin or better)

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment.

Bead Blasting

Machined parts are bead blasted with glass beads which results in a uniform grainy texture and reduced machining marks.

Tumbled

It is a process that tumbles vibrating media on machined parts to remove sharp edges and burrs. Tumbling can be used to remove machine marks from exterior surfaces.

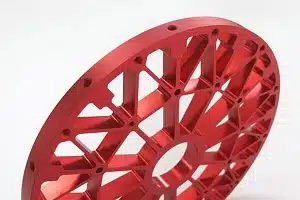

Bead blasted + Anodizing type II

The parts are bead blasted to #120 grit before being anodized type II—ideal for increasing the aluminum part’s corrosion resistance and cosmetic effects.

Bead blasted + Anodized type III (Hardcoat)

The parts are bead blasted to #120 grit before being anodized type III. Type III (Hard Coat) is thicker and adds a wear-resistant layer to Type II’s corrosion resistance, suitable for functional applications.

Black Oxide

Black oxide is a conversion coating that is used on steels to improve corrosion resistance and minimize light reflection.

Powder Coated

This is a finish of applying powdered paint to the components and then baking it in an oven, which results in a stronger, more wear- and corrosion-resistant layer that is more durable than traditional painting methods.

Chromate Conversion Coating

Chromate conversion coating is used to improve the corrosion resistance of aluminum and aluminum alloys while keeping their conductive properties. It is also applied as a base layer prior to priming and painting parts.

Plating

Include Nickel Plating, Silver Plating, Gold Plating, Zinc Plating, Chrome Plating, Tin Plating and etc, it is ideal to reduce corrosion, improve the appearance and function of solderability and electrical conductivity.

DLC (Diamond-Like Carbon) Coating

DLC (Diamond-Like Carbon) coating is a hard, wear-resistant coating made of a carbon-rich material that exhibits some of the properties of diamonds.